About Us

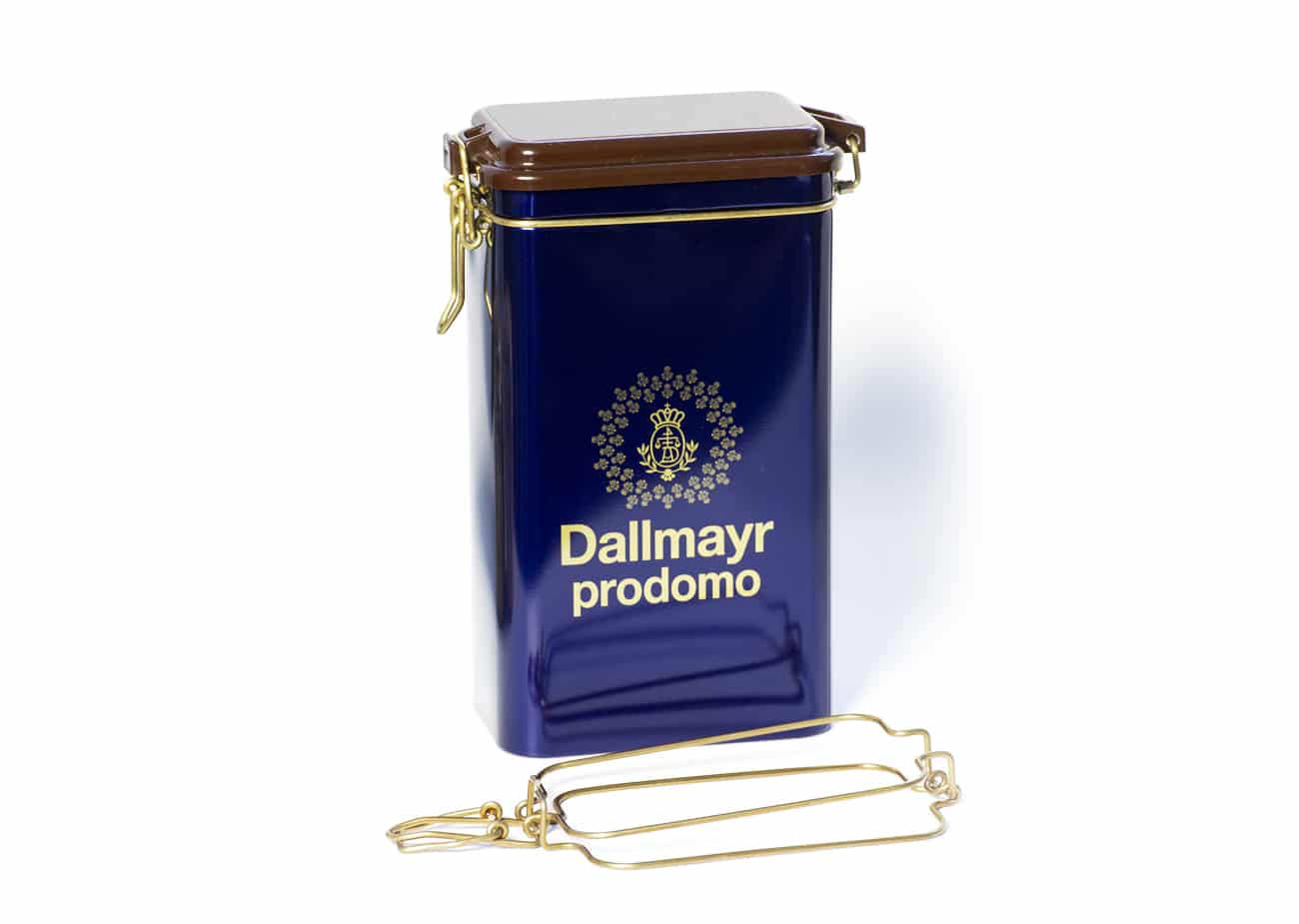

Artifil is a French manufacturer specialising in industrial metal wires and plastic injection. For over 35 years, ARTIFIL has been providing solutions to meet the needs of its customers in the mechanical closures, automotive, industry, agriculture and design sectors. From the design office up to integration in plastics-processing, every year, 660 client projects are enhanced thanks to our expertise and equipment.

+ 35 years

of experience

+ 50

employees

660

projects per year

+ 30%

turnover for exports

OUR BUSINESS SECTORS

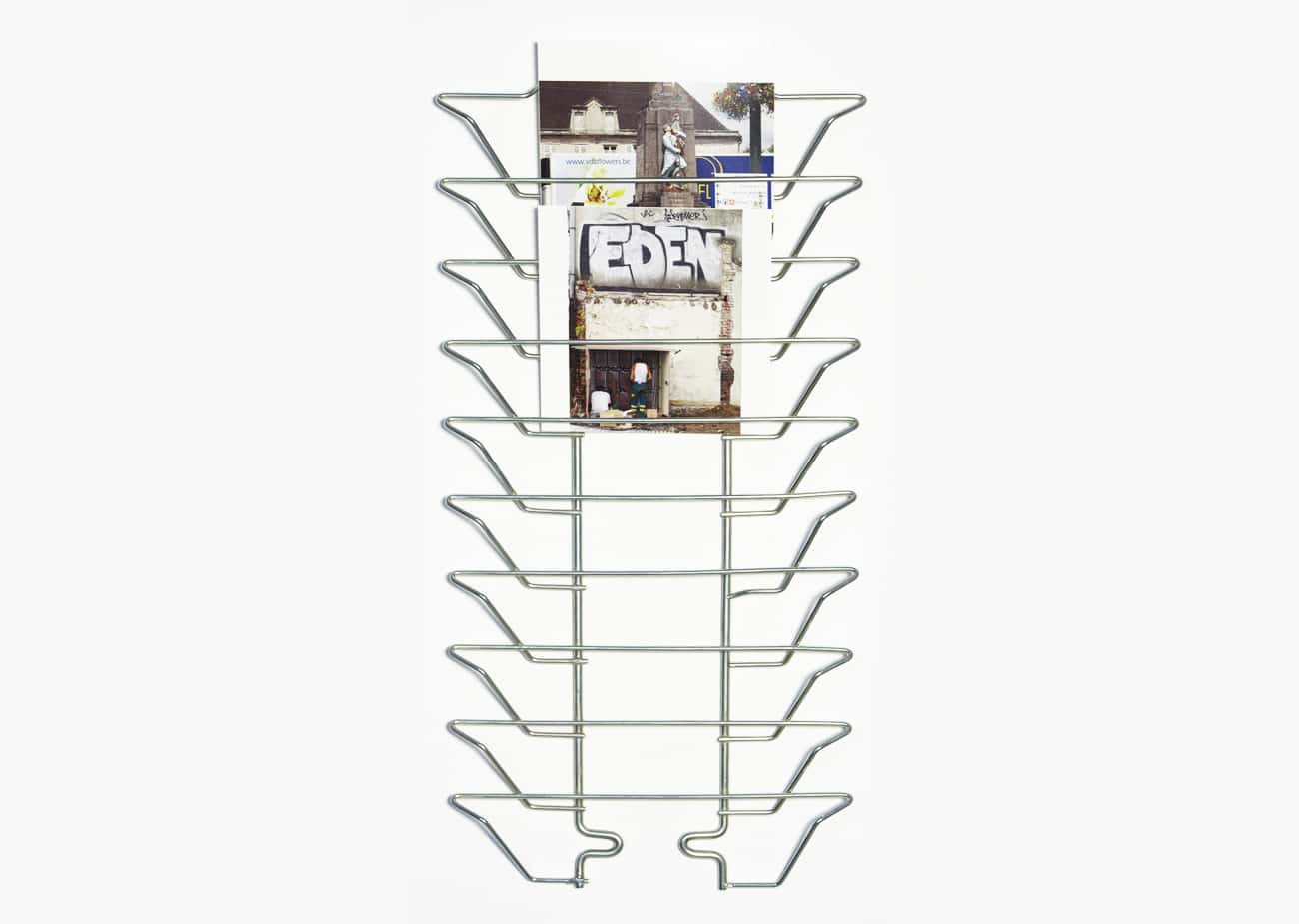

Our challenge: to transform metal wire to meet all your industrial needs.

Draw on our expertise and find out more about our achievements: learn how we can add value to your ideas,

by combining our expertise in metal wire and plastic injection.

OUR PROCESSES

Our processes target all stages – from design to industrialisation and production.

From the modelling phase up to prototyping and pre-setting in the metal wire and plastic injection industry, we are committed to working with you during the cycles in which we manage your products.

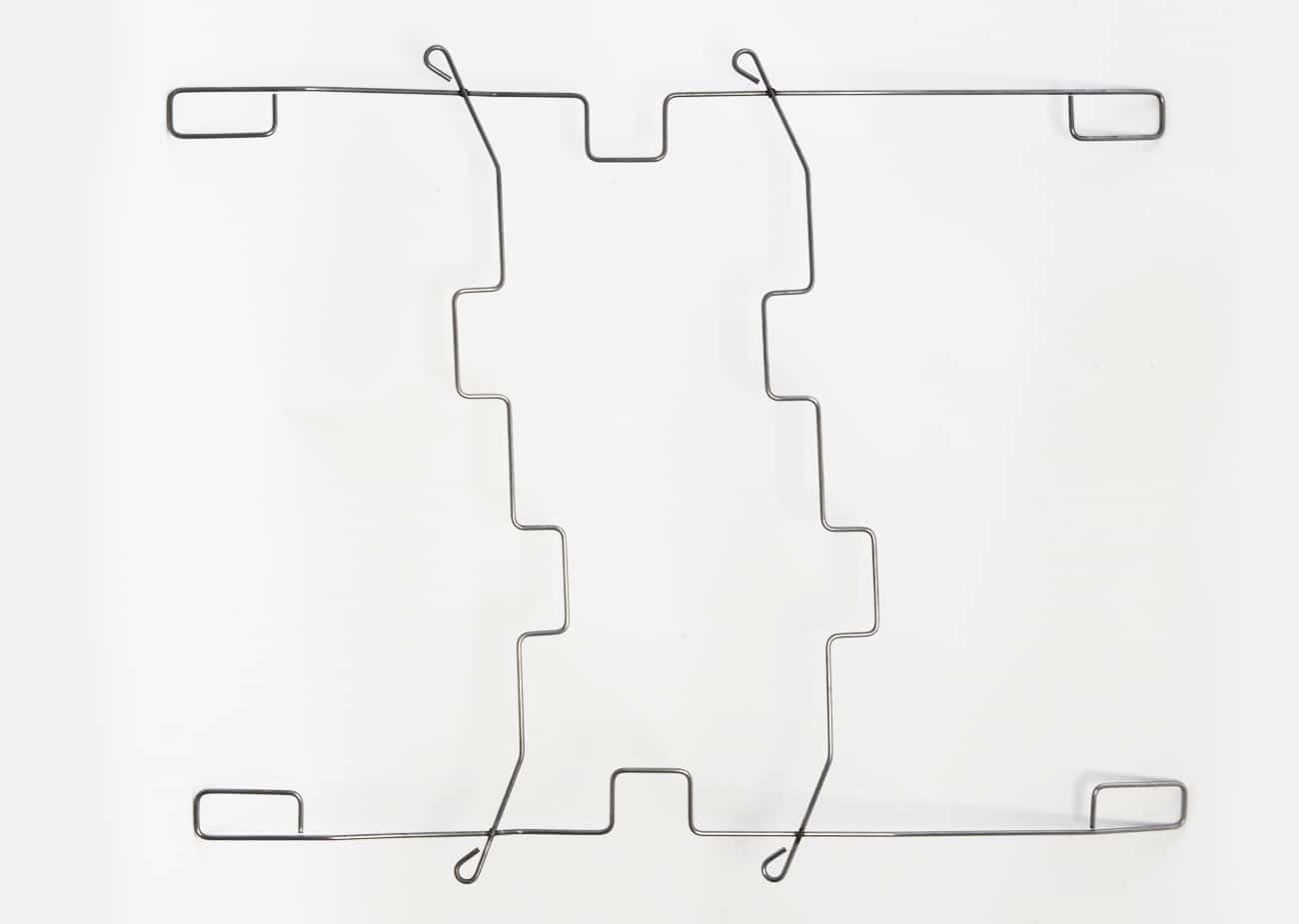

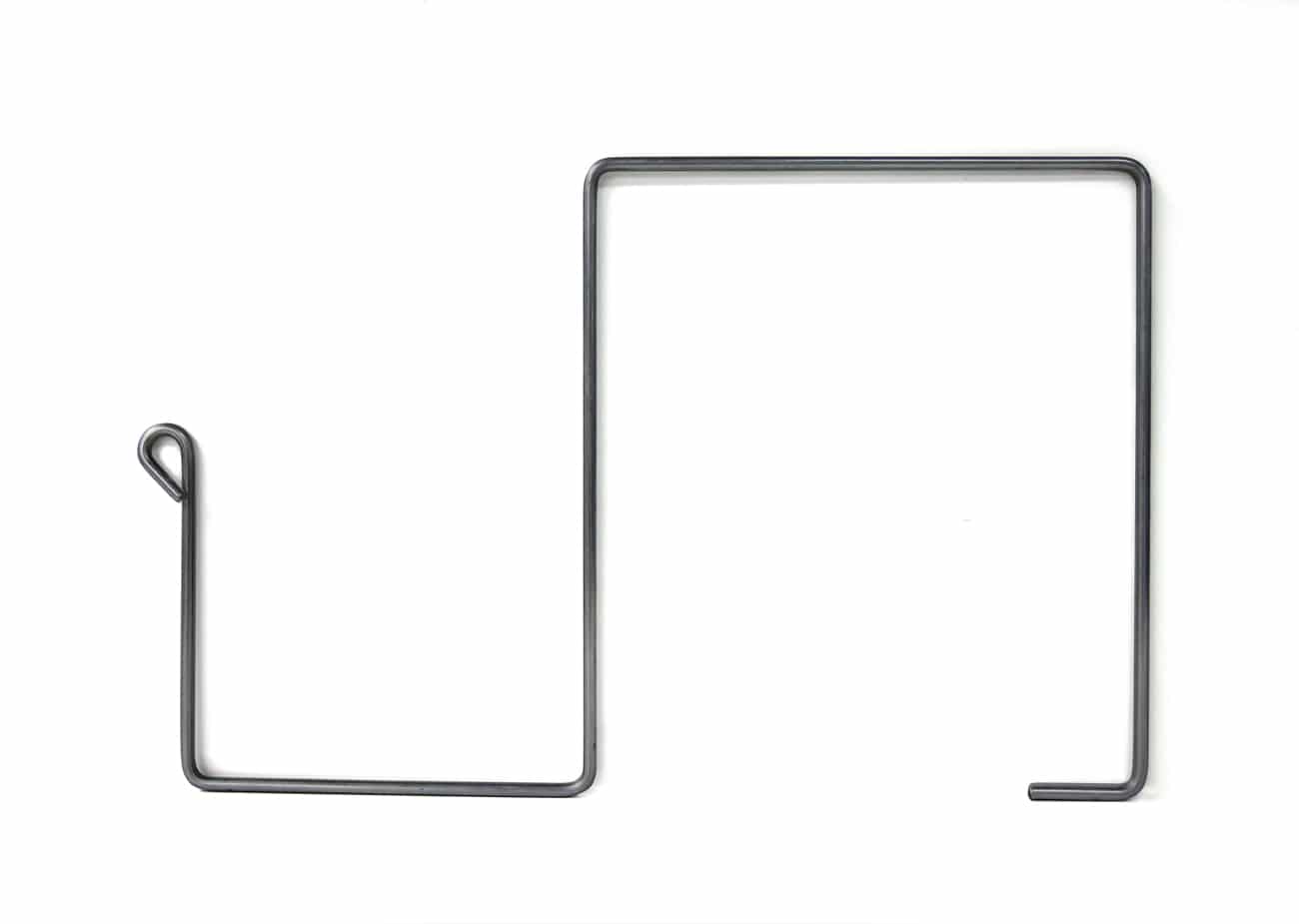

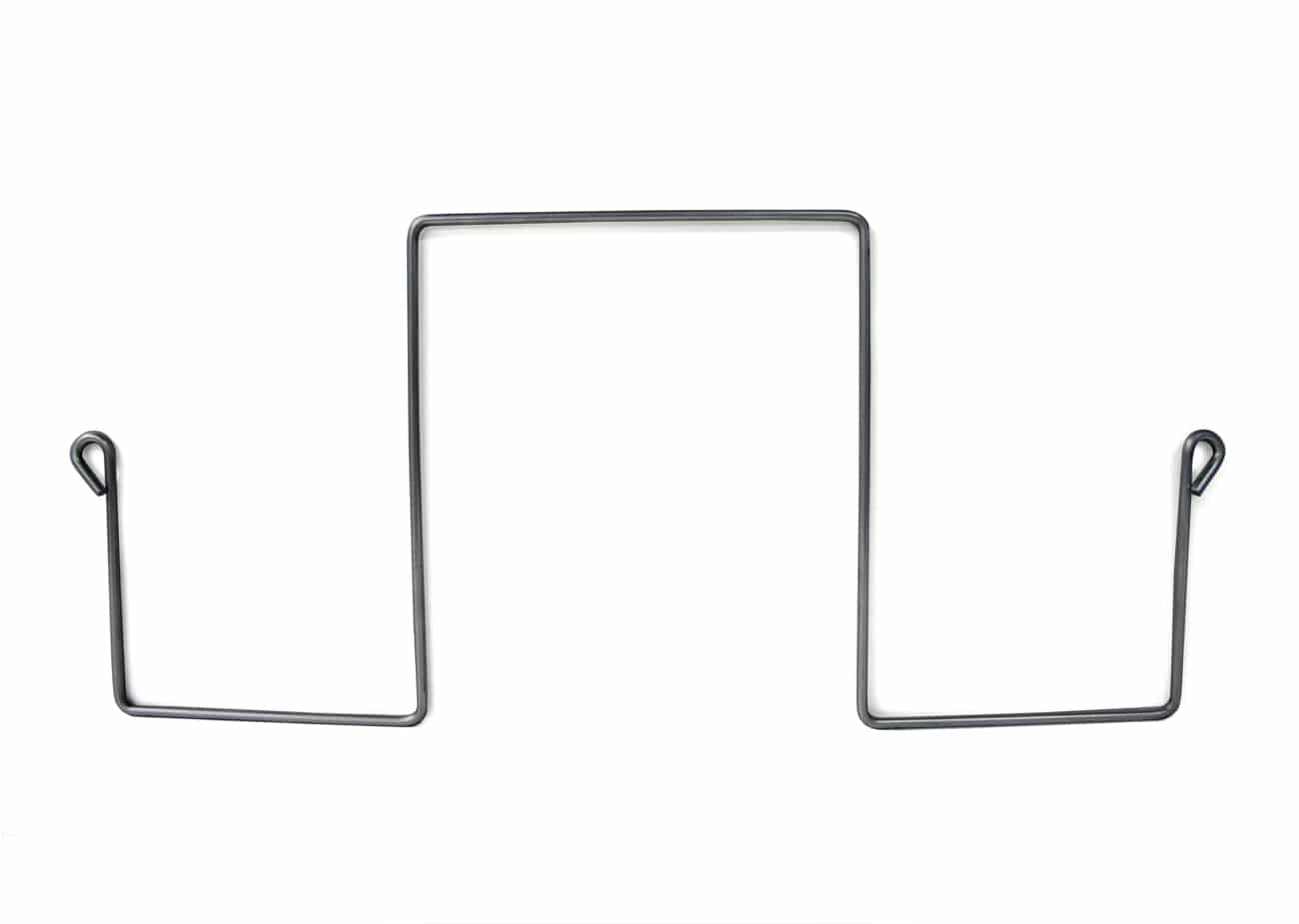

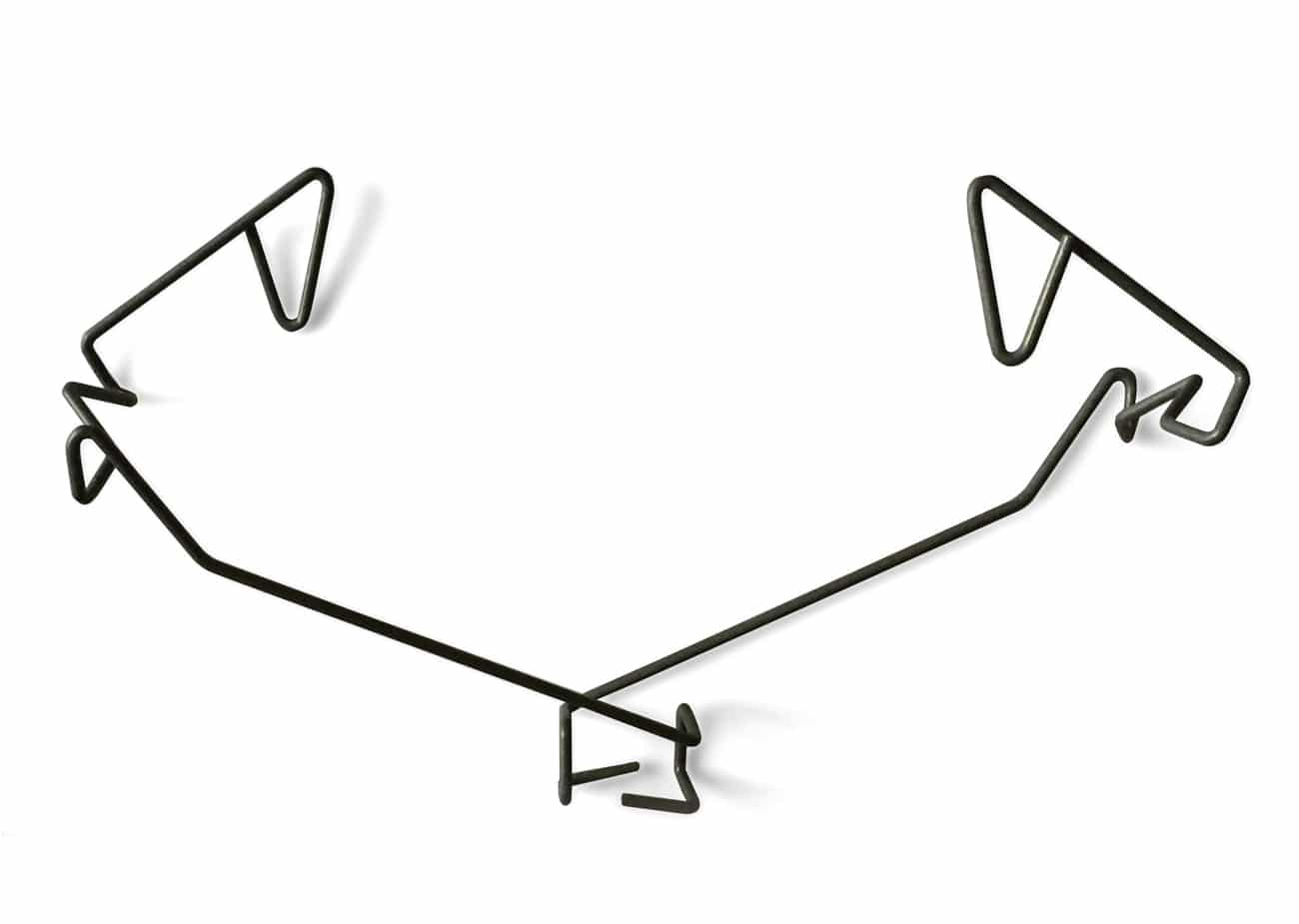

All of our equipment is integrated into processes and standards validated by their compliance with standards and certifications, some of which represent constant sources of innovation, combining both mechanical and digital tools, to add value to your client projects. Moreover, our teams precisely maintain and monitor our production tools in order to speed up and secure our operations including threading, chamfering, tapping, crushing, stamping, wire bevelling and for a single purpose: to deliver bespoke solutions for clips, pins, hooks, shafts, handles, rods or any other complex shape.